one-pot

PASSION

AND INNOVATION

One-Pot is an innovative tech company whose purpose is to put on the market a new, highly innovative process for biofuels and green chemicals, produced from residual waste.

This technology is designed to improve currently used systems and overcome critical issues such as environmental, social and economic aspects.

The partnership with the National Research Centre (CNR), has allowed One-Pot to launch an industrial research project and create a highly innovative process for the production of biodiesel and glycerol ethers (M, Di and Ter GTBE) from a single passage of any type of vegetable oil, even those characterized by high acidity such as waste oil and animal fats, or from glycerol used for the sole GTBE production.

One-Pot has patented this technology worldwide.

services

WE DELIVER

TECHNOLOGY

Research

Innovative process and pioneering vision.

Tech Transfer

We build solid relationships by sharing our expertise and technology.

Process Patenting

Our process is patented for production and granted worldwide.

tech

INNOVATIVE

TECHNOLOGY

Always committed to innovation and new technologies, One-Pot patented a process designed to overcome the environmental, social and economic critical aspects of currently used systems.

Based on an innovative process that uses a solid and acid catalyst, One-Pot technology solves the above mentioned issues, avoiding waste during the process, lowering energy consumption and enhancing overall efficiency.

ONE-POT PROCESS SYSTEM

Based on an innovative process that uses a solid and acid catalyst, One-Pot system overcomes the previous mentioned issues.

1. NO SOAP FORMATION

Therefore avoiding washes and distillation.

2. GLYCEROL FREE

The innovative process is able to provide an effective transformation of glycerol into Glycerol Ethers (GTBEs, High Value co-product).

3. DIRECT TRANSFORMATION

The process catalyzes simultaneously and efficiently three different phases: the decomposition of MTBE (tert-butyl metyl ether), the transesterification of the triglyceride and the etherification of glycerol in a one single step transformation.

4. SUSTAINABILITY

The production process has reduced amounts of carbon dioxide emissions, as well as residual and waste production.

5. WASTE OIL TREATMENT

The versatility of the process allows the use of inedible and waste vegetable oils containing amounts of free fatty acids such as exhausted frying oils from the catering industry.

6. ENERGETIC EFFICIENCY

The process has a lower power consumption (-30%) than the current production systems, thanks to the use of microwaves, that allow the cracking of the reagent in a shorter time span. Plant production itself is therefore optimized in terms of energy consumption.

7. LOWER INVESTMENT COSTS

This innovative process takes place in a single step, meaning simpler and less expensive plant structures.

market opportunities

CO-PRODUCTION

OF BIODIESEL

AND GLYCEROL

ETHERS

A revolutionary process.

Ethers

As co-product of the production of the biodiesel, One-Pot technology obtains glycerol ethers (mono, D, Tri).

Direct treatment

One-Pot technology can also treat glycerol directly and turn it into glycerol ethers.

Uses

Glycerol ethers can be used as:

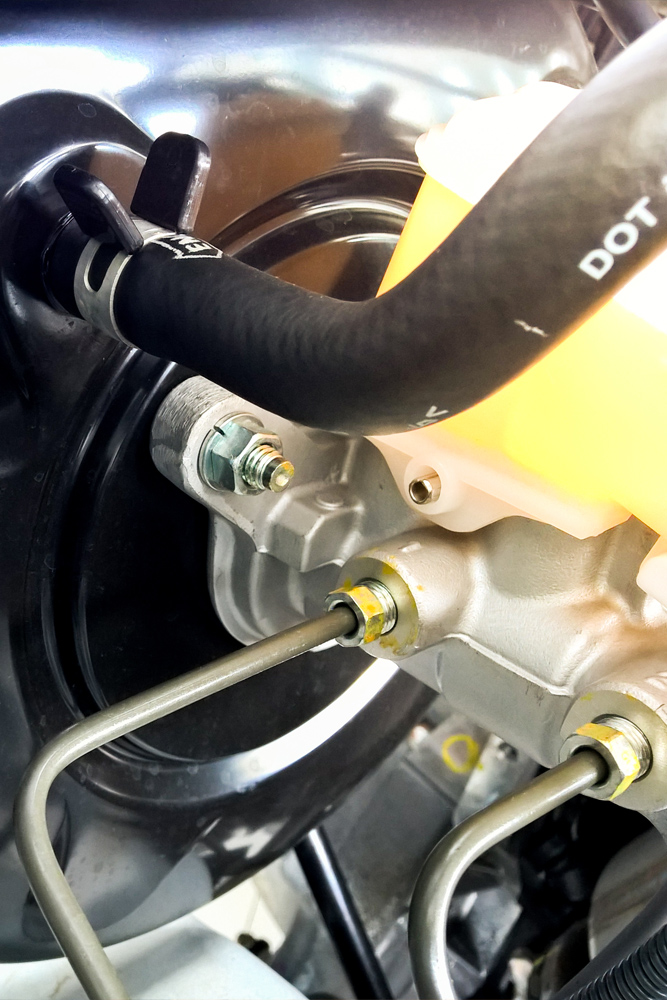

-

Hydraulic fluids

(classified dot4) -

Additive for fuels (Octane Booster)

-

Anti-icing and anti-icing for jet fuels

milestones

CONTINUOUS

IMPROVEMENT

Our growth is based on a relentless quest for value. A constant commitment, which has allowed us to reach important goals in a short time span and pushes us to set new and challenging targets every day.

There is no success without growth and there is no growth without challenges.

WORLDWIDE PATENTING

Efficient and versatile, One-Pot’s technology has been patented worldwide.

PILOT PLANT

The patent has been proved through a pilot production plant

TESTED AS HYDRAULIC FLUID

M-GTBE has been tested as a hydraulic fluid for braking systems and has been rated top of the range by a renowned potential customer.

projects

PIONEERS

BY NATURE

An ambitious approach focused on quality, sustainability and innovation, to build highly technological and innovative systems, respecting the highest quality and safety standards.

Always at work, from vision to results.

contact us

FURTHER

QUESTIONS?

Reach out to us!

Don’t hesitate to ask us something. Email us directly info@one-pot.biz or leave a message through our form. Our staff will be always open and available to you.